Products

Most

"Concentrate on product research"

AI category

Zero-code build

Zero-code Build Interactive Data is a next-generation intelligent service platform based on a self-evolving AI architecture and an all-domain Internet protocol. By deeply integrating natural language processing, real-time data analysis, and edge computing capabilities, it makes complex technologies invisible, providing users with an intelligent service experience that is zero-learning cost, highly personalized, and covers all scenarios.

Details

Cases

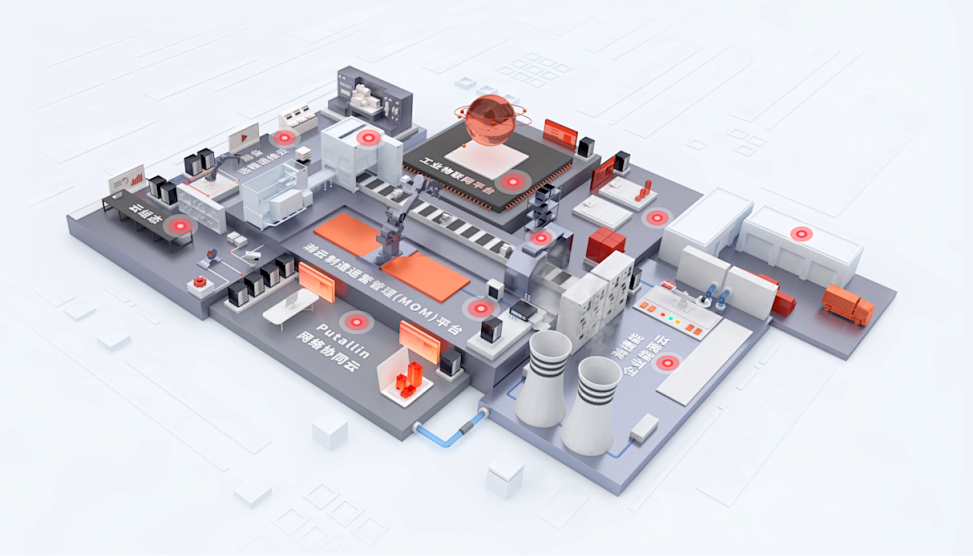

Process industry

Adopting the "GreenCore Energy Efficiency Management Service", it integrates data from over 1,000 sensors such as gas flow and air temperature, and trains an AI optimization model to dynamically adjust the coal injection volume and blower parameters.

Discrete manufacturing

Deploy the "AI-OPEX Intelligent Operation and Maintenance Platform" to monitor the health of equipment in real time through vibration sensors and edge computing, and simulate the fault propagation path in combination with digital twins

Customer Reviews

小白

经理

作为一家年采购额超50亿的制造业集团,我们曾被供应链‘黑箱’困扰多年——库存积压与缺货并存,部门间数据打架导致决策失误。引入【XX供应链中台】后,系统自动打通ERP、WMS等8大系统,实时生成‘安全库存+经济批量’动态模型。3个月内,库存周转率提升40%,缺货率归零,更让我们惊喜的是,AI自动生成的‘决策建议书’直接成为管理层会议核心依据,彻底告别‘拍脑袋’时代。 这不仅是工具升级,更是组织能力的质变。”

小黄

经理

“在汽车零部件行业,质检精度直接决定生死。过去我们依赖老师傅‘肉眼+经验’检测,漏检率高达5%,每年因质量问题损失超2000万。【XX智能质检系统】搭载工业级视觉大模型,0.1秒完成360°无死角扫描,漏检率降至0.02%,更神奇的是,它能自动分析缺陷根源(如模具磨损、温度波动),生成‘预防性维护清单’。上线6个月,我们不仅挽回损失,还因产品质量提升拿到多家头部车企订单。 这笔投资,是我们做过最正确的决策!”

小张

经理

作为一家年采购额超50亿的制造业集团,我们曾被供应链‘黑箱’困扰多年——库存积压与缺货并存,部门间数据打架导致决策失误。引入【XX供应链中台】后,系统自动打通ERP、WMS等8大系统,实时生成‘安全库存+经济批量’动态模型。3个月内,库存周转率提升40%,缺货率归零,更让我们惊喜的是,AI自动生成的‘决策建议书’直接成为管理层会议核心依据,彻底告别‘拍脑袋’时代。 这不仅是工具升级,更是组织能力的质变。”